Understanding Plastic Molding in China: A Comprehensive Guide

In the modern manufacturing landscape, plastic molding in China stands as a cornerstone of production, driving innovations and efficiencies across multiple industries. As a global leader in manufacturing, China has established a reputation for high-quality and cost-effective plastic molding solutions, making it the go-to destination for businesses around the world. This article delves deep into the nuances of plastic molding, exploring the various processes, benefits, and the prominent role that reputable companies like Hanking Mould play in this field.

The Basics of Plastic Molding

Plastic molding involves the manufacturing of plastic parts through various processes. The most common methods include:

- Injection Molding

- Blow Molding

- Rotational Molding

- Thermoforming

- Compression Molding

Each of these processes has its unique applications, advantages, and use cases, making it crucial for companies to select the appropriate method based on their specific needs.

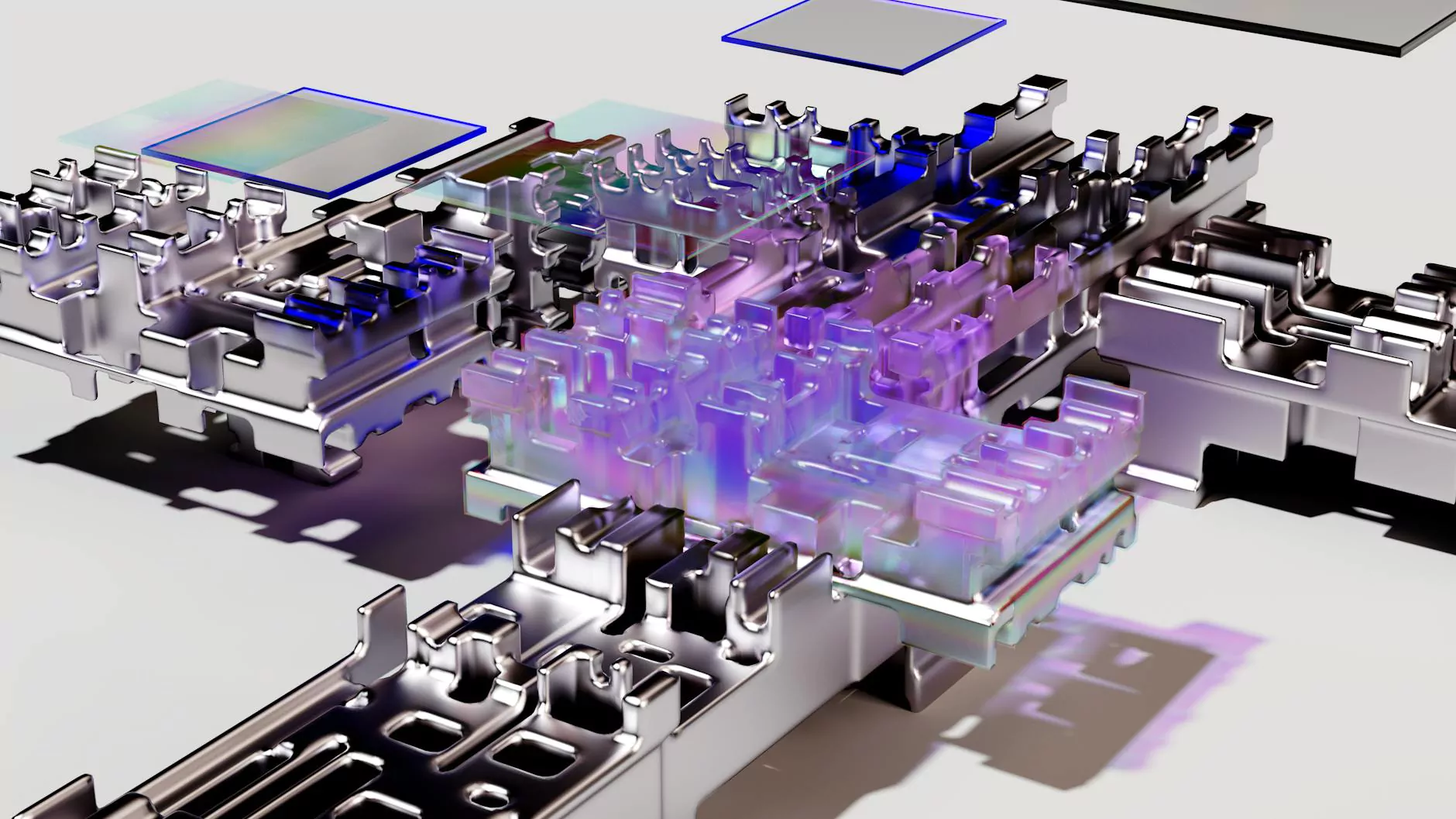

Injection Molding: The Heart of Plastic Manufacturing

Among the various methods of plastic molding, injection molding is the most widely used due to its efficiency and ability to produce complex shapes with high precision. This process involves the injection of molten plastic into a mold, where it cools and solidifies to form the desired part.

Why Choose Injection Molding?

- High Speed Production: Capable of producing thousands of parts rapidly, making it ideal for large volume outputs.

- Complex Geometries: Enables the creation of intricate shapes that would be difficult or impossible to achieve with other methods.

- Material Versatility: Compatible with a wide range of thermoplastics and thermosetting polymers.

- Minimal Waste: The process maximizes material use, resulting in lower production costs over time.

The Role of Plastic Mold Makers

Plastic mold makers are essential for the success of any plastic molding project. They design, manufacture, and maintain the molds used in the injection molding process. A competitive company like Hanking Mould excels in this area, offering:

Expertise and Precision

With a team of skilled engineers and designers, Hanking Mould provides precise and tailored solutions to meet specific client requirements. This expertise is vital for ensuring that the final products meet high-quality standards.

Advanced Technology

Investing in state-of-the-art machinery and technology facilitates the production of molds that offer superior durability and performance, further enhancing the efficiency of the molding process.

Benefits of Sourcing Plastic Molding from China

China's dominance in the plastic molding industry is not merely due to lower costs; there are several advantages that make it a preferred choice for businesses worldwide:

- Cost Efficiency: China offers competitive pricing without compromising on quality, which is especially beneficial for startups and established companies alike.

- Large Scale Production: The ability to cater to both small and large orders allows businesses to scale their operations as needed.

- Access to Skilled Workforce: A vast pool of skilled labor and engineers ensures high-quality production standards and innovative solutions.

- Robust Supply Chain: Established logistics and supply chains streamline operations, reducing lead times and ensuring timely deliveries.

Trends in Plastic Molding in China

The plastic molding industry in China is evolving rapidly, driven by technological advancements and changes in consumer demand. Some notable trends include:

Sustainable Practices

As global awareness about the environment grows, more companies are investing in sustainable practices. This includes utilizing biodegradable materials and implementing energy-efficient processes to minimize their carbon footprint.

Automation and Industry 4.0

The integration of automation and smart technologies into the manufacturing process is becoming increasingly prevalent. Adopting Industry 4.0 principles allows plastic molders to enhance efficiency, reduce errors, and improve overall production quality.

Customization and Shorter Lead Times

In today's fast-paced market, there is a growing demand for customized solutions. Companies that can provide tailored molding services with shorter lead times are positioned for success.

Choosing the Right Plastic Injection Mould Manufacturer

Selecting the right plastic injection mould manufacturer is critical for the success of your project. Here are some factors to consider:

- Experience: Look for manufacturers with a proven track record in the industry. Experience often translates to better understanding and execution of projects.

- Portfolio: Review the company's portfolio to gauge their capabilities and the diversity of their past projects.

- Quality Certifications: Verify that the manufacturer holds relevant quality certifications, reflecting their commitment to maintaining high standards.

- Customer Support: Ensure that the manufacturer offers robust customer support for any queries or concerns during the project lifecycle.

Conclusion: The Future of Plastic Molding in China

As we dive deeper into the world of manufacturing, the significance of plastic molding in China continues to rise. Companies like Hanking Mould are at the forefront, paving the way for innovation and excellence in this vital sector. With advancements in technology, a focus on sustainability, and increasing customization demands, the future of plastic molding remains bright. Businesses looking to excel in their respective fields must consider the myriad opportunities presented by engaging with reputable plastic molding services in China.

In conclusion, whether you are a startup or an established corporation, tapping into the vast resources available in China's plastic molding landscape can lead to remarkable growth and success. Embrace the future of manufacturing with confidence, knowing that the right partner in plastic molding can deliver unparalleled results.

plastic molding china