Comprehensive Guide to Vacuum Membranes: Unlocking Opportunities in Business Growth

In the rapidly evolving world of industrial manufacturing, the importance of innovative materials and technologies cannot be overstated. Among these, vacuum membranes have emerged as a game-changing solution that enhances efficiency, quality, and sustainability across various sectors. From coating applications to filtration systems, vacuum membranes offer unparalleled advantages that can significantly elevate your business operations. This comprehensive guide explores the depth and breadth of vacuum membranes, focusing on their features, applications, and how they can be a strategic asset in your commercial portfolio.

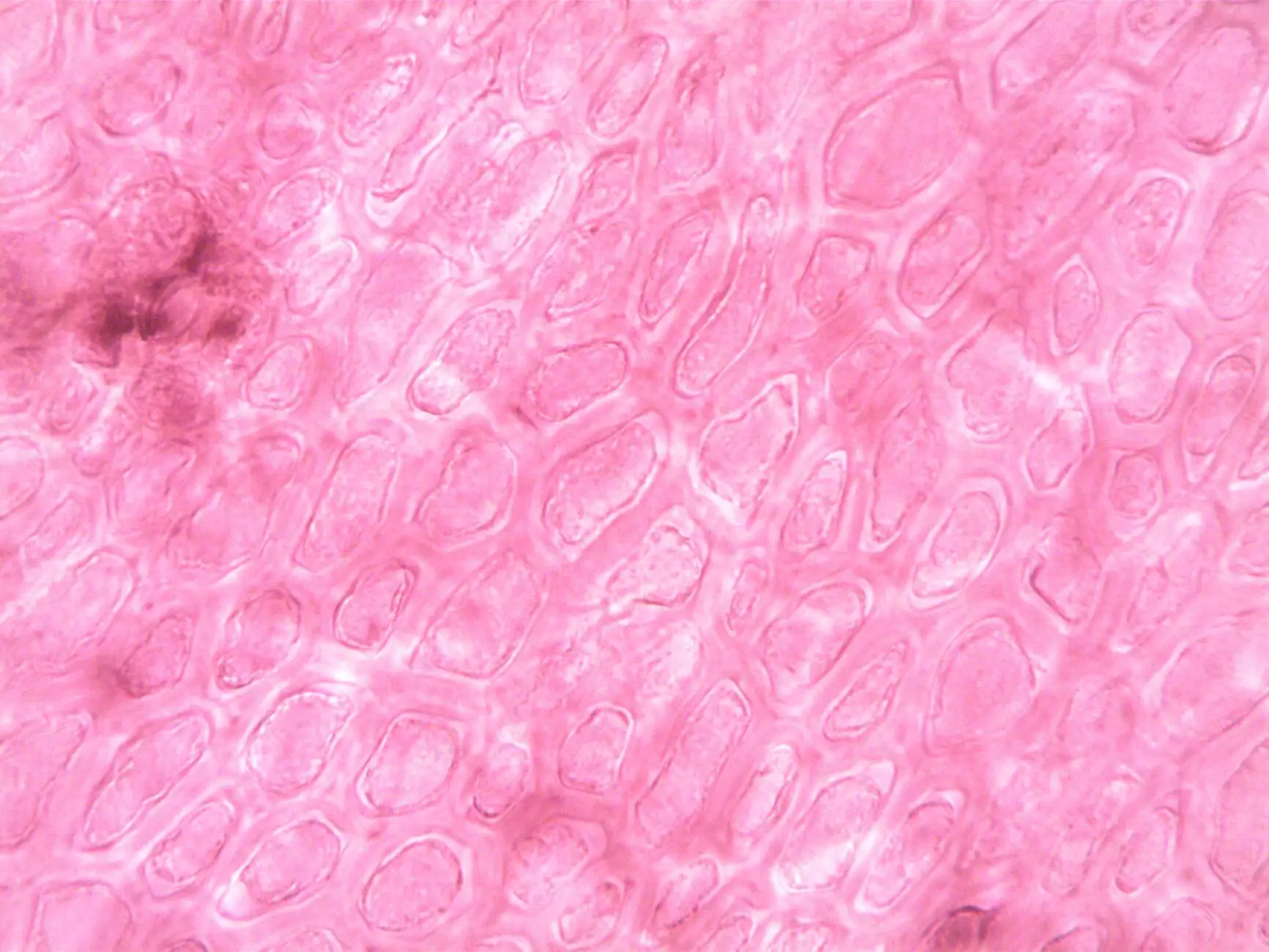

What Is a Vacuum Membrane?

A vacuum membrane is a specialized material layer designed to function within vacuum-based systems, providing a barrier that controls gas, liquid, or vapor flow under specific conditions. These membranes are engineered to withstand pressure differentials, maintain integrity in challenging environments, and facilitate processes like separation, filtration, or coating. Their unique properties allow industries to optimize processes that were previously complex, costly, or inefficient.

The Role of Vacuum Membranes in Modern Industries

Vacuum membranes have become indispensable in various sectors, including electronics, healthcare, environmental engineering, and construction. They are particularly valuable in applications that require precise control over material transfer, contamination prevention, or energy conservation. Here are some key roles:

- Filtration and Separation: Ensuring high purity in liquids and gases.

- Coating Processes: Achieving uniform application of materials like silicone or rubber onto surfaces.

- Water and Waste Treatment: Removing impurities efficiently while reducing chemical usage.

- Rubber and Silicone Membranes Production: Manufacturing resilient, flexible membranes for various applications.

- Vacuum-Assisted Manufacturing: Enhancing the precision and speed of industrial fabrication processes.

Advantages of Using Silicone and Rubber Membranes

Silicone and rubber membranes are at the forefront of vacuum membrane technology, offering remarkable benefits:

- High Flexibility: Accommodate movement and deformation without losing performance.

- Superior Chemical Resistance: Withstand aggressive substances, ensuring longevity.

- Thermal Stability: Operate effectively across wide temperature ranges.

- Excellent Barrier Properties: Prevent leaks and contamination, crucial for sensitive applications.

- Ease of Installation and Maintenance: Reduce downtime and operational costs.

Applications of Vacuum Membranes in Business

Harnessing the potential of vacuum membranes can lead to substantial business advantages. Here’s how various industries leverage these membranes:

1. Silicone Membranes for Sale in Industry

Silicone membranes are renowned for their exceptional durability and chemical inertness. Businesses utilize these membranes for applications such as:

- Sealants and gaskets in machinery requiring high-temperature resistance

- Flexible barriers in semiconductor fabrication

- Protective coatings for industrial equipment

- Components in medical devices due to biocompatibility

- Membrane bioreactors in wastewater treatment plants

The availability of high-quality silicone membranes for sale in specialized shops ensures businesses can access these advanced materials at competitive prices, enabling innovation and efficiency.

2. Rubber Membranes for Sale and Their Business Benefits

Rubber membranes are versatile and cost-effective, suitable for a variety of demanding environments. They are extensively used in:

- Waterproofing and hydraulic systems

- Vibration isolation in heavy machinery

- Protective barriers in chemical processing

- Hydraulic seals and diaphragms

- Soundproofing applications

Opting for durable rubber membranes through a reputable rubber membrane shop ensures continuous operation, reduces maintenance costs, and enhances safety standards.

Why Choose High-Quality Vacuum Membranes?

Investing in high-quality vacuum membranes from trusted suppliers like silicone-membranes.eu offers significant advantages such as improved performance, longer service life, and compliance with industry standards. High-quality membranes ensure:

- Consistent Process Outcomes: Uniformity in manufacturing processes leading to superior product quality.

- Operational Efficiency: Reduced downtime due to fewer failures or replacements.

- Cost Savings: Lower maintenance and replacement costs over time.

- Environmental Sustainability: Reduced waste and energy consumption.

Advances in Vacuum Membrane Technology

The field of vacuum membrane technology continues to evolve with innovations such as:

- Nanocomposite Membranes: Offering enhanced strength and selectivity.

- Smart Membranes: Incorporating sensors to monitor conditions in real-time.

- Eco-Friendly Materials: Reducing environmental impact in manufacturing and disposal.

- Modular Design: Facilitating easy installation, maintenance, and scalability.

These technological breakthroughs create new business opportunities, enabling companies to develop cutting-edge products and services that meet the demanding needs of modern markets.

Choosing the Right Vacuum Membrane Supplier

To harness the full potential of vacuum membranes, selecting a reliable and experienced supplier is critical. Key considerations include:

- Product Range: Availability of diverse membrane types like silicone, rubber, and specialized composites.

- Quality Assurance: Certifications and testing standards that guarantee performance and safety.

- Technical Support: Expert guidance on installation, maintenance, and application best practices.

- Cost-Effectiveness: Competitive pricing without compromising quality.

- Delivery and Logistics: Timely supply to meet production schedules.

Partnering with silicone-membranes.eu ensures access to world-class products and tailored solutions that align with your business objectives.

Future Trends and Business Opportunities in Vacuum Membranes

As industries demand higher efficiency, sustainability, and technological sophistication, the vacuum membrane market is poised for substantial growth. Emerging trends include:

- Integration with Internet of Things (IoT) for predictive maintenance

- Development of biodegradable and environmentally friendly membranes

- Enhanced customization options for niche applications

- Global expansion into emerging markets

- Collaboration across industries to develop multifunctional membranes

Businesses investing in advanced vacuum membrane solutions today can position themselves at the forefront of innovation, gaining a competitive advantage in their respective markets.

Conclusion: Embracing the Power of Vacuum Membranes in Business Strategy

In conclusion, the adoption of vacuum membranes presents an extraordinary opportunity to transform your business operations, enhance product quality, and reduce environmental impact. Whether you are looking to upgrade your current manufacturing process, expand your product line, or enter new markets, investing in high-quality silicone and rubber membranes from reputable suppliers is a strategic move. The continuous evolution of vacuum membrane technology promises a future filled with innovation, efficiency, and sustainable growth.

Seize the opportunity today by exploring the extensive range of membranes available at silicone-membranes.eu—your trusted partner in advancing industrial excellence and business success.